Fabrication

Hawk

Fabrication

Our fabrication shop is 39,000 square feet underroof and is situated on 10 acres with adequate laydown yard storage and staging areas.

Safety is our goal and we strive for perfection.

Our commitment to safety is paramount, reflected through daily safety meetings that foster a culture of awareness and responsibility. Emphasizing zero tolerance for drug and alcohol use, our comprehensive training programs encompass Short Service Employee Training and Mentorship initiatives. We prioritize accountability and ownership with sign-in protocols, coupled with proactive measures such as near miss and incident investigations. Our dedication to continuous improvement is evident in our robust incident reporting procedures, which include RCRA compliance and lessons learned. Internally conducted safety inspections, complemented by quarterly audits, further ensure the highest standards of safety across our operations.

Fabrication

Hawk Fabrication Product Offerings and Capabilities

Certified Welding Inspector on location (David Salinas our General

Manager) ENGINEERING

CERTIFICATIONS INCLUDED:

- WCS

- ABS

- AWS

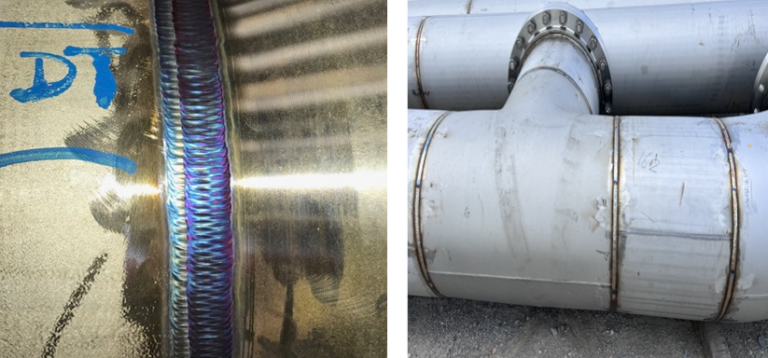

WELDING PROCESSES INCLUDE THE FOLLOWING

- Gas Tungsten Arc Welding

- Flux Core ARC Welding

- Shielded Metal ARC Welding

- Submerged ARC Welding

PROCESS PIPEING INCLUDE’S THE FOLLOWING WITH QA/QC CODE ADHERENCE

- ASME B31:3

- API 1104

- ASME:31.4

- ASME 313.8

FABRICATION AND PROCESS PIPING MATERIALS

Carbon Steel Included but Not Limited to:

- A106 GRADE B AND API 5L

- Steel materials Included in our Processes

- with unlimited possibilities

- 304, 316, 310, 312, 2205

PROCESS PIPEING

FLARE STACK ASSEMBLY

OUR STRUCTURAL STEEL D1-1 FABRICATION IS UNLIMITED

- Ladders

- Embeds

- Elevated Walkways

- Loading/Pipe/ Panel Racks

- T, Cable Tray, Pipe, and many other supports

- Platform of all size and materials (Bolted & Welded)

- SKIDS (All different shapes, sizes and ASME requirements)

MISCELLANEOUS STEEL FABRICATION INCLUDES BUT NOT LIMITED TO

- Grating

- Handrails

- Ladders

- Caged Ladders

- Stairs and stair treads

MULTIPROCESS WELDING MACHINES INCLUDED

- Gas Tungsten TIG Welding

- Flux Core ARC Welding

- Shielded Metal ARC Welding

- Submerged ARC Welding

SINGLE PROCESS WELDING MACHINES

- Gas Wire Machines

AC POWERED MACHINES

- Aluminum Wire Spool

- Aluminum TIG Welding

SHEAR

- Cut Material From 1/16” to ½” and 10” Wide Plate

ELLIS MITRE SAW

- 13’ 6” X 1” Blade

- 90 Degree Flat Cut

- 13-1/2” Round at 90 Degree

- 13” Round at 45 Degree

SCOTCHMAN MACHINE

- Punch Holes From ¾” to 1-1/16”

- Notch Handrail Materials

- Cut Flat Bar ¾” to 24”

IRON WORKING INCLUDES

- Punched Holes 1” THRU 1-3/8”

- 1-1/16” THRU 1-1/4”

BURN TABLES 5’ X 10’ CNC PLASMA TABLE 1/16th

thru ¾

- Precisely Cut materials including:

- Carbon

- Aluminum

- Stainless

MESSER 8’ X 20’ CNC PLASMA TABLE

- Aluminum

- Carbon

- Material Thickness’s Up to the Following 1/8” TO 1-1/2”

PLATE ROLLING CAPABILITIES

- Minimum Diameter 12”

- Maximum Diameter 20’ (In Sections)

- Material Width’s Include 10’

- Material Thickness’s Include 1/8” TO 5/8”

CONE PLATE ROLLING CAPABILITIES

PRESS BRAKE

- Material Thickness 1/16” to 3/18”

- Material Width 1’’ to 6’’

PUNCH

- 50 Ton Punch

- Hole Punching abilities from 11 ga to ¾”

- Hole size from ¼” to 1”

OVERHEAD CRANE

- 10 ton

- 5 ton

HYDMECH 20A SAW

- Cuts from 45 to 90-degree angles

- 20 feet in height and 30 feet wide

PAINT BOOTH

- 70’ in length X 40’ in width X 16’ in height

BLAST BOOTH

- 40’ in length X 40’ wide X 16’ in height

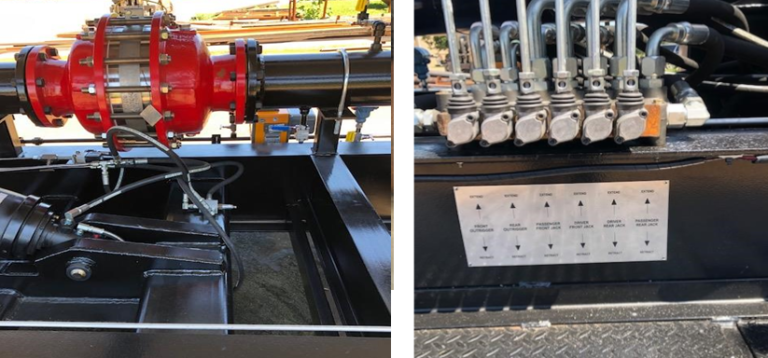

DOT ELECTRICAL CONNECTIONS AND CUSTOM TANKER MODIFICATIONS

- We install DOT electrical wiring and hook up per your specifications

HYDRAULICS AND INSTRUMENT TUBING

- Installation of hydraulic fittings and components including:

- Cylinders

- Hoses

- Instrument Tubing

HAWK EPC

Safety

First

The safety of our people and yours comes FIRST.